Good batch: good glass.

It’s that simple.

And getting the batch to be good is where our expertise comes into play.

Zippe glass batch plants ensure that the batch for every glass type is fed fully automatically into the melter with the exact consistency and homogeneity required, at the required amount and at the right point in time – 24 hours a day, every day.

Your system, exactly to size, no matter what size.

Innovative and solution-oriented, our team of experts ensures smooth and on-schedule realization of every project from single machines to turnkey solutions. Leading global companies place their trust in our professionalism and experience because we channel all our energy and effort into continual development, innovation and safety.

Our unflagging endeavors are what make Zippe a preferred partner for all our customers and the key to your efficient glass production – right from the start.

Good batch

good glass

It’s that simple.

And getting the batch to be good is where our expertise comes into play.

Zippe glass batch plants ensure that the batch for every glass type is fed fully automatically into the melter with the exact consistency and homogeneity required, at the required amount and at the right point in time – 24 hours a day, every day.

Your system, exactly to size, no matter what size.

Innovative and solution-oriented, our team of experts ensures smooth and on-schedule realization of every project from single machines to turnkey solutions. Leading global companies place their trust in our professionalism and experience because we channel all our energy and effort into continual development, innovation and safety.

Our unflagging endeavors are what make Zippe a preferred partner for all our customers and the key to your efficient glass production – right from the start.

Dosing and weighing

Collecting Belt Conveyor

Small components (premix)

Mixing

Inline plants

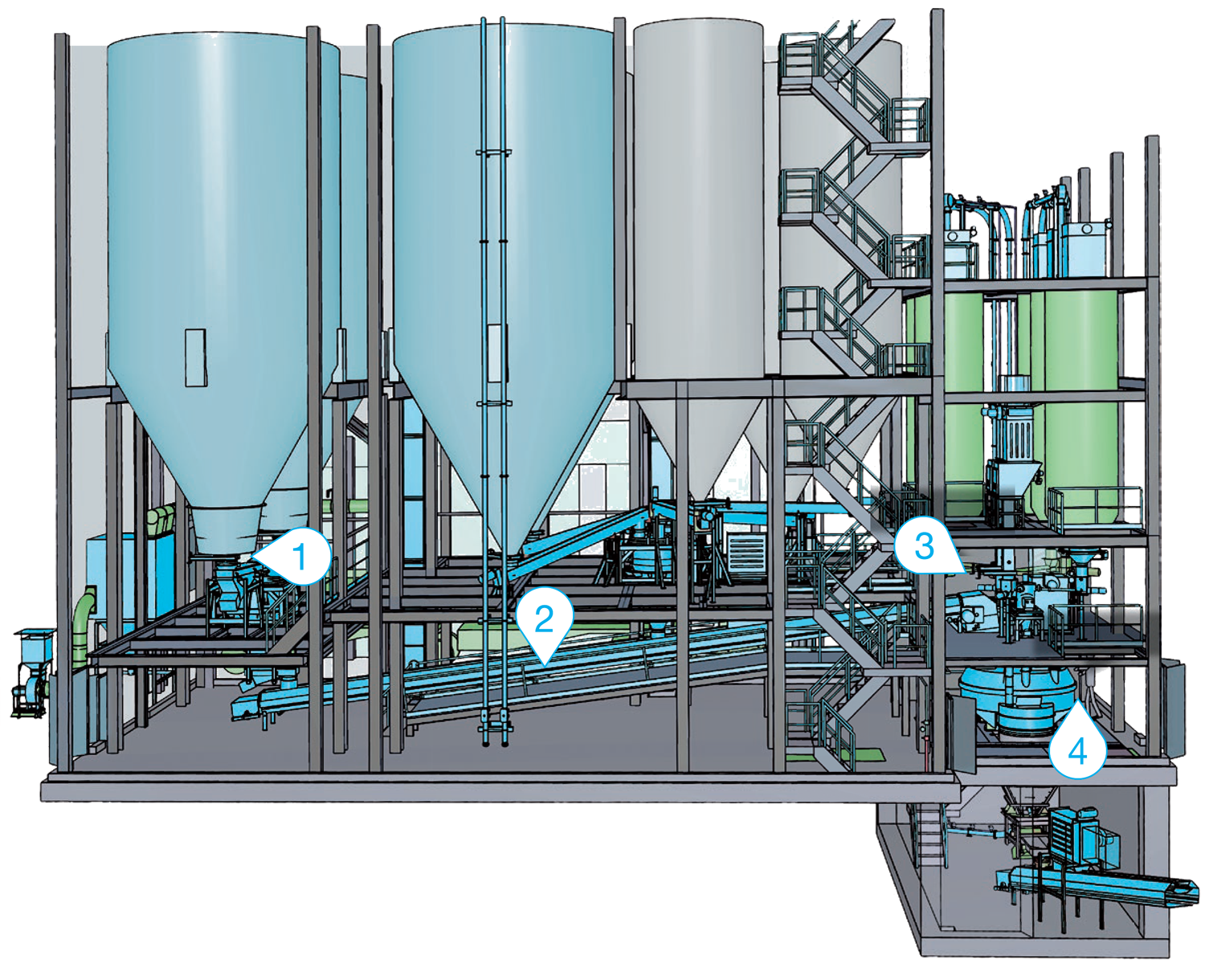

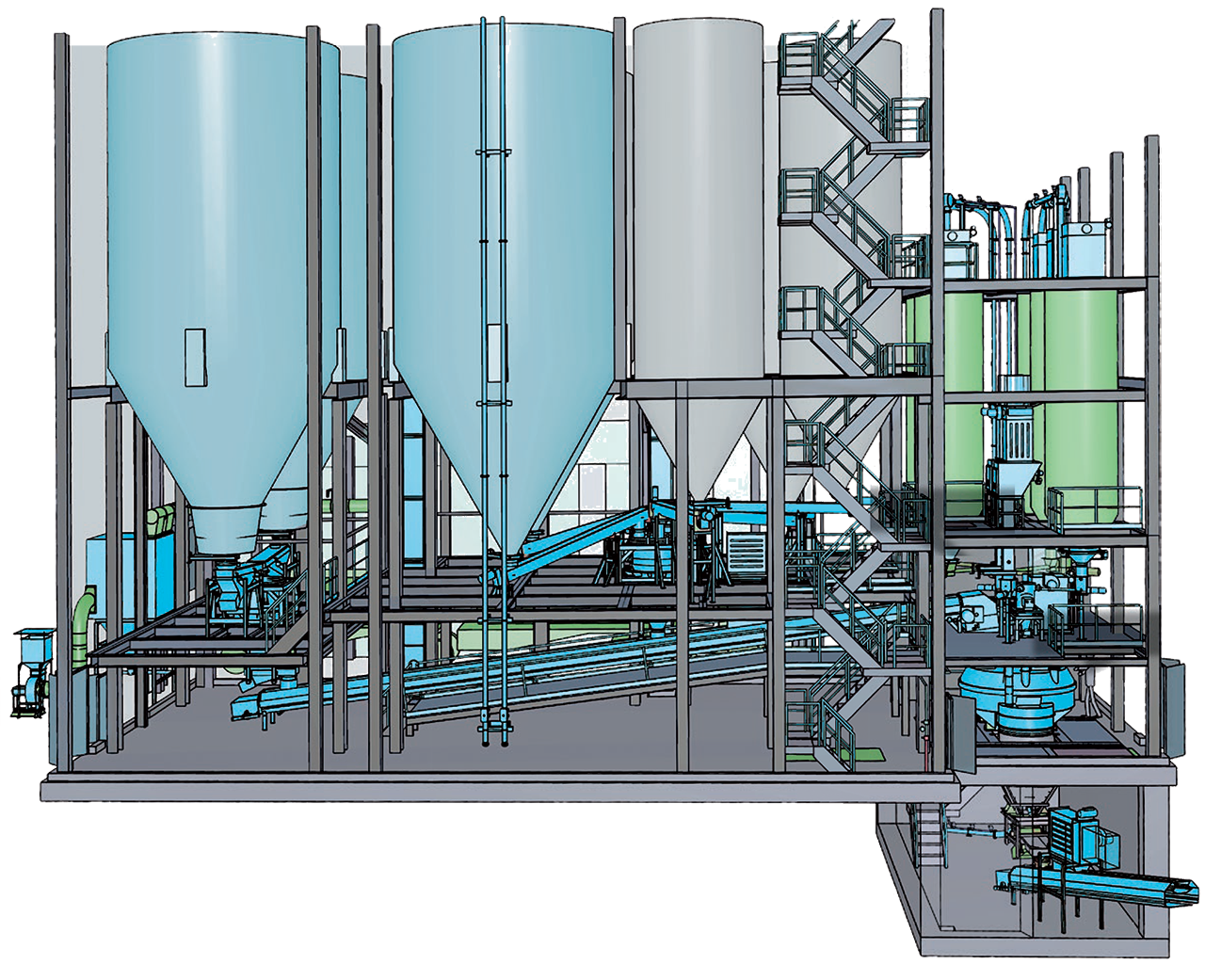

Flexible, for medium to large production volumes

In inline plants, the silos are arranged next to each other in a row. These plants are ideal for medium to large outputs (150 to 1,200 t per day), and are used when various raw materials, silos and formulations are required.

The more silos are needed, the more scales are required. In an inline plant these can be arranged more flexibly. All scales empty out onto a collecting belt conveyor which transports the weighed raw materials to the mixer. Inline plants can also be equipped with several mixers.

This enables supplying several furnaces with batch, e.g. for different glass colors. The advantage of inline plants, however, is their flexibility. These plants can subsequently be expanded with additional silos and scales in order to, for example, increase production or to produce additional types of glass.

Inline plants

Flexible, for medium to large production volumes

In inline plants, the silos are arranged next to each other in a row. These plants are ideal for medium to large outputs (150 to 1,200 t per day), and are used when various raw materials, silos and formulations are required.

The more silos are needed, the more scales are required. In an inline plant these can be arranged more flexibly. All scales empty out onto a collecting belt conveyor which transports the weighed raw materials to the mixer. Inline plants can also be equipped with several mixers.

This enables supplying several furnaces with batch, e.g. for different glass colors. The advantage of inline plants, however, is their flexibility. These plants can subsequently be expanded with additional silos and scales in order to, for example, increase production or to produce additional types of glass.

Key

- Dosing and weighing

- Collecting Belt Conveyor

- Small components (premix)

- Mixing

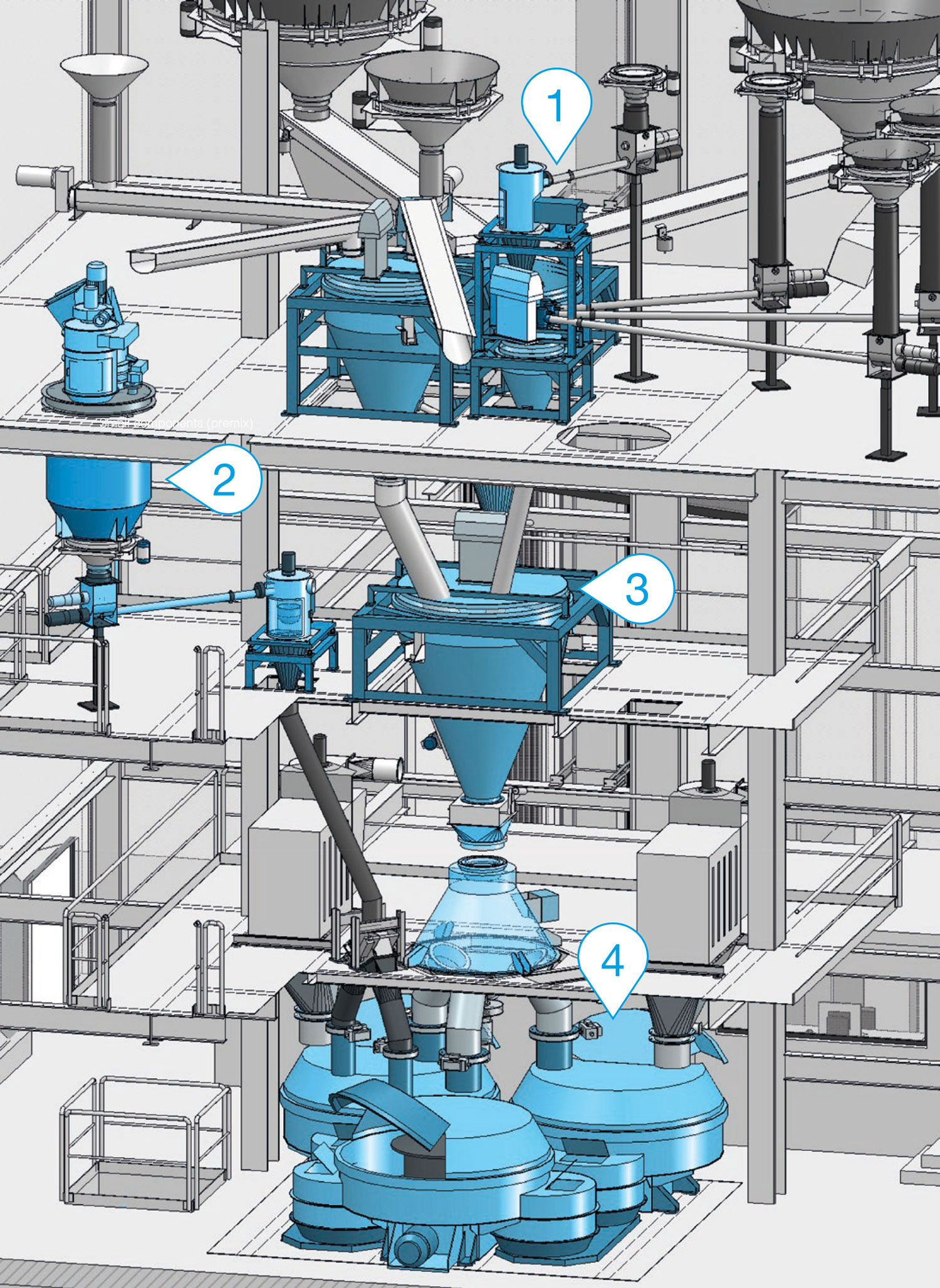

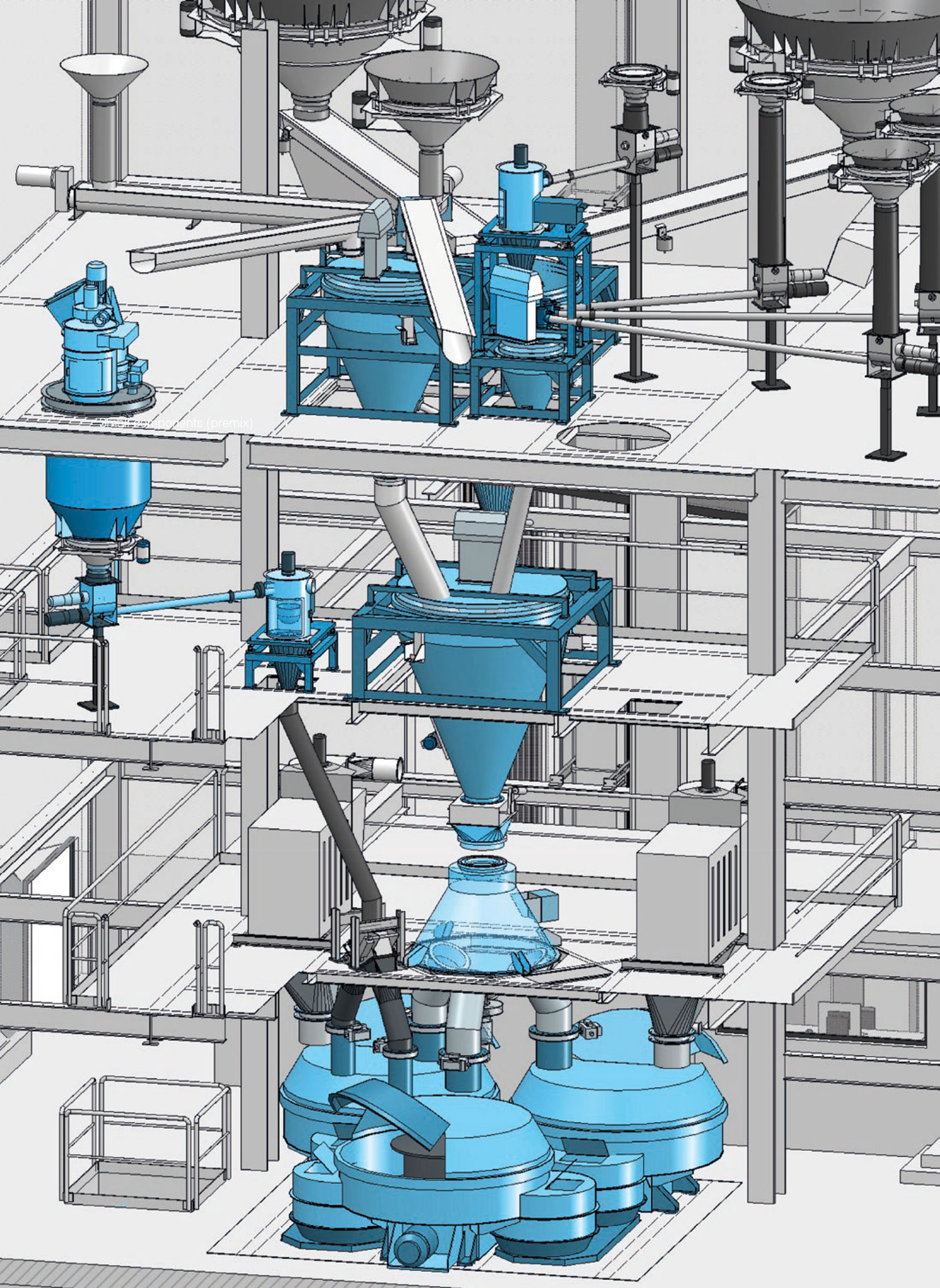

Tower

plants

Compact, for small to medium production volumes

Tower plants are designed for small to medium capacities (10 to 450 t per day). They are normally equipped with one, but can also be equipped with multiple mixers and can supply several melting furnaces. The silos or the raw material scales are arranged above the mixer and empty directly into it.

The difference to the inline plant is the lack of a collecting belt, which is advantageous in terms of dust development. Due to the lower output, tower plants can be designed very compactly and therefore only require a relatively small area.

Dosing and weighing

Small components (premix)

Check scale

Mixing

Tower

plants

Compact, for small to medium production volumes

Tower plants are designed for small to medium capacities (10 to 450 t per day). They are normally equipped with one, but can also be equipped with multiple mixers and can supply several melting furnaces. The silos or the raw material scales are arranged above the mixer and empty directly into it.

The difference to the inline plant is the lack of a collecting belt, which is advantageous in terms of dust development. Due to the lower output, tower plants can be designed very compactly and therefore only require a relatively small area.

Key

- Dosing and weighing

- Small components (premix)

- Check scale

- Mixing

Concrete or Steel Silos

Most batch plants are designed with steel silos. This allows for greater flexibility. For example, additional steel silos can be planned into the plant right from the start and can be cost effectibely retrofitted at a later stage. Concrete silos, on the other hand, are often used where there is a need for very high furnace capacity (over 800 t per day) and high silo storage.

Whether a plant is designed as a concrete or steel structure depends on the installation site, since country-specific regulations regarding, for example, earthquakes or weather conditions, must be taken into account.

Concrete or Steel Silos

Most batch plants are designed with steel silos. This allows for greater flexibility. For example, additional steel silos can be planned into the plant right from the start and can be cost effectibely retrofitted at a later stage. Concrete silos, on the other hand, are often used where there is a need for very high furnace capacity (over 800 t per day) and high silo storage.

Whether a plant is designed as a concrete or steel structure depends on the installation site, since country-specific regulations regarding, for example, earthquakes or weather conditions, must be taken into account.

No matter what kind of glass you produce, with Zippe you’re right from the start.

Container Glass

The term “container glass” includes the most commonly produced glass products today, e.g. drinking bottles of all types or preserving and packaging glass. On average, anywhere between 50–90% of post-consumer glass is used during production. The majority of container glass is made from soda-lime glass.

Characteristics of container glass

The color of glass is often changed (flint, green, amber) to enable flexible production. Plants must be able to fulfill all color spectrums.

- Higher ratio of cullet, up to 90%

- Cullet handling plays an important role

- Higher wear protection very important (because of the higher ratio of cullet)

No matter what kind of glass you produce, with Zippe you’re right from the start.

Container Glass

The term “container glass” includes the most commonly produced glass products today, e.g. drinking bottles of all types or preserving and packaging glass. On average, anywhere between 50–90% of post-consumer glass is used during production. The majority of container glass is made from soda-lime glass.

Characteristics of container glass

The color of glass is often changed (flint, green, amber) to enable flexible production. Plants must be able to fulfill all color spectrums.

- Higher ratio of cullet, up to 90%

- Cullet handling plays an important role

- Higher wear protection very important (because of the higher ratio of cullet)

Float Glass

Any glass in flat form is described as float glass, regardless of the manufacturing process. The most common manufacturing process for flat glass is the float glass process. However, float glass can also be producedas pattern glass. Float glass products are primarily used for windows or architectural glass during construction.

Other areas of use include automotive glass, mirrors, solar glass for photovoltaic and solar thermal energy. For most of these applications, the glass produced is subjected to additional processing in order to adapt it to the corresponding conditions where it will be used.

Characteristics of float glass

- Plants produce considerably more output than container glass production

- Lower (external) ratio of cullet

- First Zippe float glass plant in 1984

- The furnaces do not require such frequent color changes

Float Glass

Any glass in flat form is described as float glass, regardless of the manufacturing process. The most common manufacturing process for flat glass is the float glass process. However, float glass can also be producedas pattern glass. Float glass products are primarily used for windows or architectural glass during construction.

Other areas of use include automotive glass, mirrors, solar glass for photovoltaic and solar thermal energy. For most of these applications, the glass produced is subjected to additional processing in order to adapt it to the corresponding conditions where it will be used.

Characteristics of float glass

- Plants produce considerably more output than container glass production

- Lower (external) ratio of cullet

- First Zippe float glass plant in 1984

- The furnaces do not require such frequent color changes

Special Glass

Typically, special glass includes display glass for computer screens, televisions and smartphones (TFT, LCD) and must meet very specific requirements. This requires scientific studies, which only very few manufacturers conduct. The results of these studies are special glasses with high chemical and thermal resistance as well as glasses with various special optical or electrochemical properties. These glasses are used in, for example, industries such as chemicals, pharmaceuticals, electrical engineering, electronics, apparatus engineering and optics.

Characteristics of special glass

- Many small components

- High accuracy required when weighing

- Extensive expertise needed when handling raw materials

- “Low iron” partially required

- Special glass is characterized by its properties, such as its high optical purity and homogeneity, chemical resistance, or temperature change resistance

Special Glass

Typically, special glass includes display glass for computer screens, televisions and smartphones (TFT, LCD) and must meet very specific requirements. This requires scientific studies, which only very few manufacturers conduct. The results of these studies are special glasses with high chemical and thermal resistance as well as glasses with various special optical or electrochemical properties. These glasses are used in, for example, industries such as chemicals, pharmaceuticals, electrical engineering, electronics, apparatus engineering and optics.

Characteristics of special glass

- Many small components

- High accuracy required when weighing

- Extensive expertise needed when handling raw materials

- “Low iron” partially required

- Special glass is characterized by its properties, such as its high optical purity and homogeneity, chemical resistance, or temperature change resistance

Fiber Glass

Fiber glass consists of long, thin fibers. During production, thin fibers are pulled from a glass melt and further processed into any number of end products. Fiber glass is used, for example, for cables to transmit data and flexibly transmit light, for instance laser beams. As roving or as a textile fiber, they are used in heat and sound insulation as well as in plastics reinforcement.

Fiber glass products are resistant to ageing, weathering and chemicals and are fire-proof. Their high elasticity makes these products ideal for improving the mechanical properties of plastics. In addition, their ability to transmit light is used in various technical applications. Fiber glass is almost always produced by means of the nozzle drawing process.

Characteristics of fiber glass

- Predominantly light and very dry raw materials require certain characteristics in the batch plant regarding

- Design (tower plant)

- Transportation (pneumatic)

- Mixing process (pneumatic blender)

Fiber Glass

Fiber glass consists of long, thin fibers. During production, thin fibers are pulled from a glass melt and further processed into any number of end products. Fiber glass is used, for example, for cables to transmit data and flexibly transmit light, for instance laser beams. As roving or as a textile fiber, they are used in heat and sound insulation as well as in plastics reinforcement.

Fiber glass products are resistant to ageing, weathering and chemicals and are fire-proof. Their high elasticity makes these products ideal for improving the mechanical properties of plastics. In addition, their ability to transmit light is used in various technical applications. Fiber glass is almost always produced by means of the nozzle drawing process.

Characteristics of fiber glass

- Predominantly light and very dry raw materials require certain characteristics in the batch plant regarding

- Design (tower plant)

- Transportation (pneumatic)

- Mixing process (pneumatic blender)

Continuous Flexibility

The Zippe BWS™ belt conveyor

When dosing continuous streams of bulk material, flexibility is a necessity. This requirement is reliably met with a high level of accuracy, by the Zippe dosing belt conveyor, across the threshold range. Dosing belt conveyors can be used practically everywhere, especially in the container glass industry. They are characterized by their compact size. Zippe has its own dosing belt conveyor system.

Continuous Flexibility

The Zippe BWS™ dosing belt conveyor

When dosing continuous streams of bulk material, flexibility is a necessity. This requirement is reliably met with a high level of accuracy, by the Zippe dosing belt conveyor, across the threshold range. Dosing belt conveyors can be used practically everywhere, especially in the container glass industry. They are characterized by their compact size. Zippe has its own dosing belt conveyor system.

Keep up with Zippe

Subscribe to our newsletter to receive the latest news directly.