Safer in the long run…

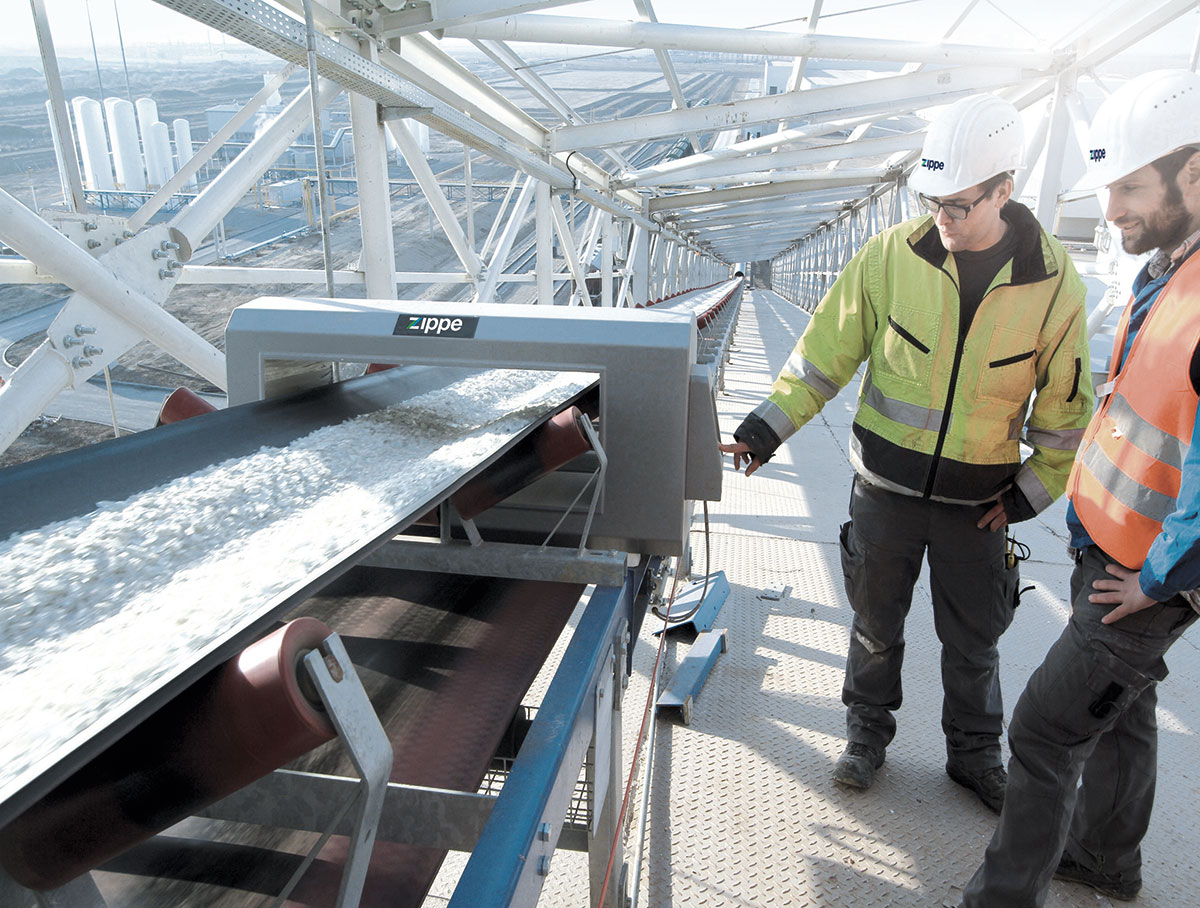

The Zippe Plant Check is a complete package which includes all work and services required for a thorough examination of your plant. This determines if and which repairs and parts are necessary.

Of course, we adapt the plant check according to the requirements of your plant.

Why a Zippe Plant Check?

Nowadays, nobody can afford unscheduled plant downtimes caused by unforeseen repairs or insufficient utilization of plant potential.

Numerous factors can develop over the years that affect the functional reliability of your plant components:

- Wear and damage of plant components

- Modified operating parameters that have changed in the course of the plant operating time

- Changed safety standards

- Outdated hardware and software

- Discontinued components (no longer available from the system supplier) and so forth…

Safer in the long run…

The Zippe Plant Check is a complete package which includes all work and services required for a thorough examination of your plant. This determines if and which repairs and parts are necessary.

Of course, we adapt the plant check according to the requirements of your plant.

Why a Zippe Plant Check?

Nowadays, nobody can afford unscheduled plant downtimes caused by unforeseen repairs or insufficient utilization of plant potential.

Numerous factors can develop over the years that affect the functional reliability of your plant components:

- Wear and damage of plant components

- Modified operating parameters that have changed in the course of the plant operating time

- Changed safety standards

- Outdated hardware and software

- Discontinued components (no longer available from the system supplier) and so forth…

…with higher performance and lower risk

The scope of the Zippe Plant Check in detail:

- Thorough check of all mechanical and electrical components

- Smaller adjustments during the plant check, together with the customer staff

- Review and calibration of your scales

- Analysis of production processes

- On request, check of spare parts in stock

- Travel and accommodation costs are included

- Detailed final report with description of the defects/discrepancies found regarding maintenance and inspection

- Suggestions for future preventive measures

…with higher performance and lower risk

The scope of the Zippe Plant Check in detail:

- Thorough check of all mechanical and electrical components

- Smaller adjustments during the plant check, together with the customer staff

- Review and calibration of your scales

- Analysis of production processes

- On request, check of spare parts in stock

- Travel and accommodation costs are included

- Detailed final report with description of the defects/discrepancies found regarding maintenance and inspection

- Suggestions for future preventive measures

Benefits of a Zippe Plant Check

The preventive inspection of your plant provides certainty about its actual condition and gives you reliability and optimal production quality.

- Reduction of unscheduled plant downtime

- Reduction of maintenance servicee

- Reduction of repair and maintenance costs

- Optimization of energy cost

- Effective monitoring of plant status

- Improvement of maintenance routines

- Optimization of plant potential and plant parameters

Benefits of a Zippe Plant Check

The preventive inspection of your plant provides certainty about its actual condition and gives you reliability and optimal production quality.

- Reduction of unscheduled plant downtime

- Reduction of maintenance servicee

- Reduction of repair and maintenance costs

- Optimization of energy cost

- Effective monitoring of plant status

- Improvement of maintenance routines

- Optimization of plant potential and plant parameters

Keep up with Zippe

Subscribe to our newsletter to receive the latest news directly.