Exact measuring –

it’s all in the details

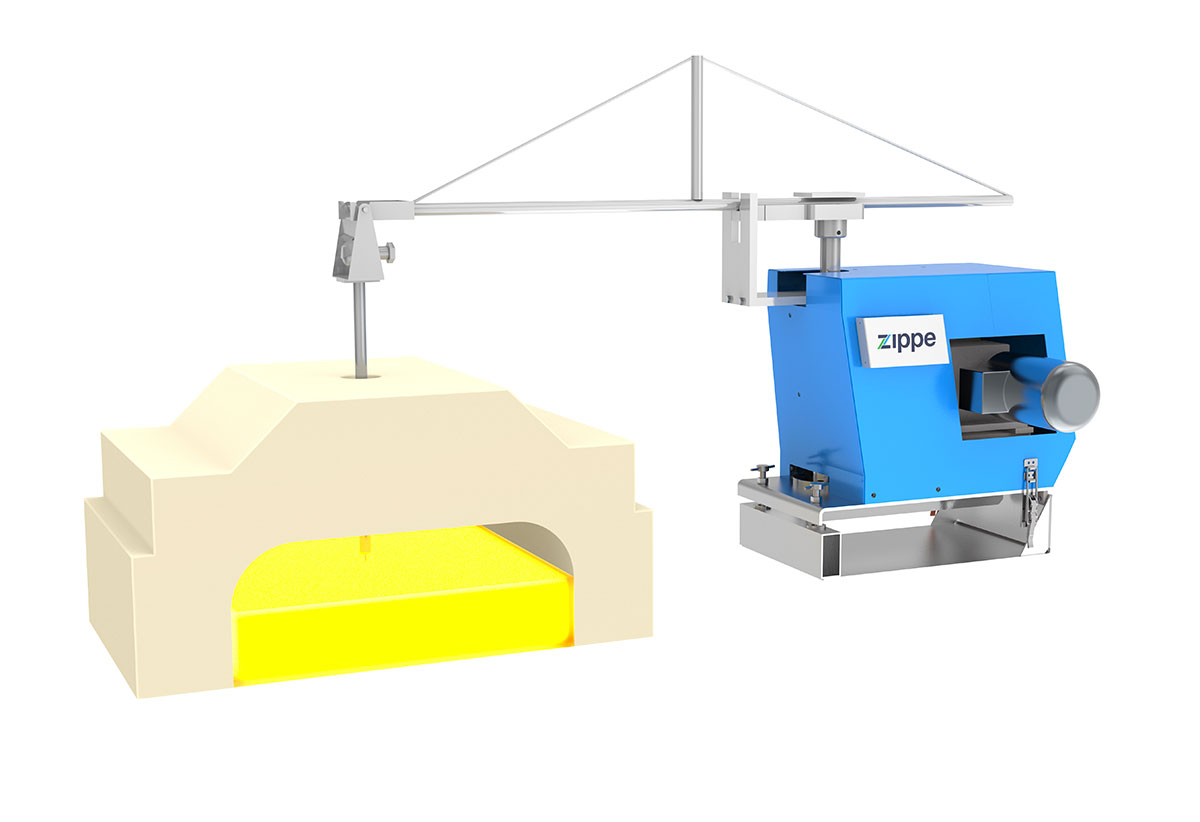

Highly advanced measurement and control systems ensure exact and reliable determination of the glass level in the furnace during the melting operation. If the glass level sinks below a specified level, a signal is automatically relayed to the batch charger that then feeds new molten material into the furnace.

BZ 24 Mechanical Glass Level Control System for Container Glass Furnaces

The glass level measuring system is available in two versions: firstly the BZ 24 S/H, with a water-cooled electrode, for installation directly at the furnace, for measuring through the side wall, and secondly the BZ 24 S/V, with a ceramic electrode, for installation at the feeder, for measuring through the feeder.

Features at a glance

- Fully digital processing of measured values

- Parameterization of the measuring system in dialogue via control unit or web interface

- Text display of measuring status

- Integrated proportional regulator usable for batch charger control. Optional

bus connection to higher level control possible - The control and display unit, as well as the chart recorder, can be

mounted in a control cabinet of the furnace control room

independently of the glass level measuring system - Reliable mechanical equipment, low maintenance

Exact measuring –

it’s all in the details

Highly advanced measurement and control systems ensure exact and reliable determination of the glass level in the furnace during the melting operation. If the glass level sinks below a specified level, a signal is automatically relayed to the batch charger that then feeds new molten material into the furnace.

BZ 24 Mechanical Glass Level Control System for Container Glass Furnaces

The glass level measuring system is available in two versions: firstly the BZ 24 S/H, with a water-cooled electrode, for installation directly at the furnace, for measuring through the side wall, and secondly the BZ 24 S/V, with a ceramic electrode, for installation at the feeder, for measuring through the feeder.

Features at a glance

- Fully digital processing of measured values

- Parameterization of the measuring system in dialogue via control unit or web interface

- Text display of measuring status

- Integrated proportional regulator usable for batch charger control. Optional

bus connection to higher level control possible - The control and display unit, as well as the chart recorder, can be

mounted in a control cabinet of the furnace control room

independently of the glass level measuring system - Reliable mechanical equipment, low maintenance

Keep up with Zippe

Subscribe to our newsletter to receive the latest news directly.